Freightliner Repair and Replacements

There are many parts to a freightliner that require repairs or replacement during their lifetime. This is essential for maintaining the functionality and safety of commercial vehicles. Regular maintenance and timely repairs ensure that freightliner trucks and systems operate efficiently, reducing downtime and costly breakdowns. Replacement of worn-out components or systems is crucial for extending the lifespan of the vehicle and ensuring it meets regulatory standards, ultimately contributing to the reliability and profitability of a fleet operation.

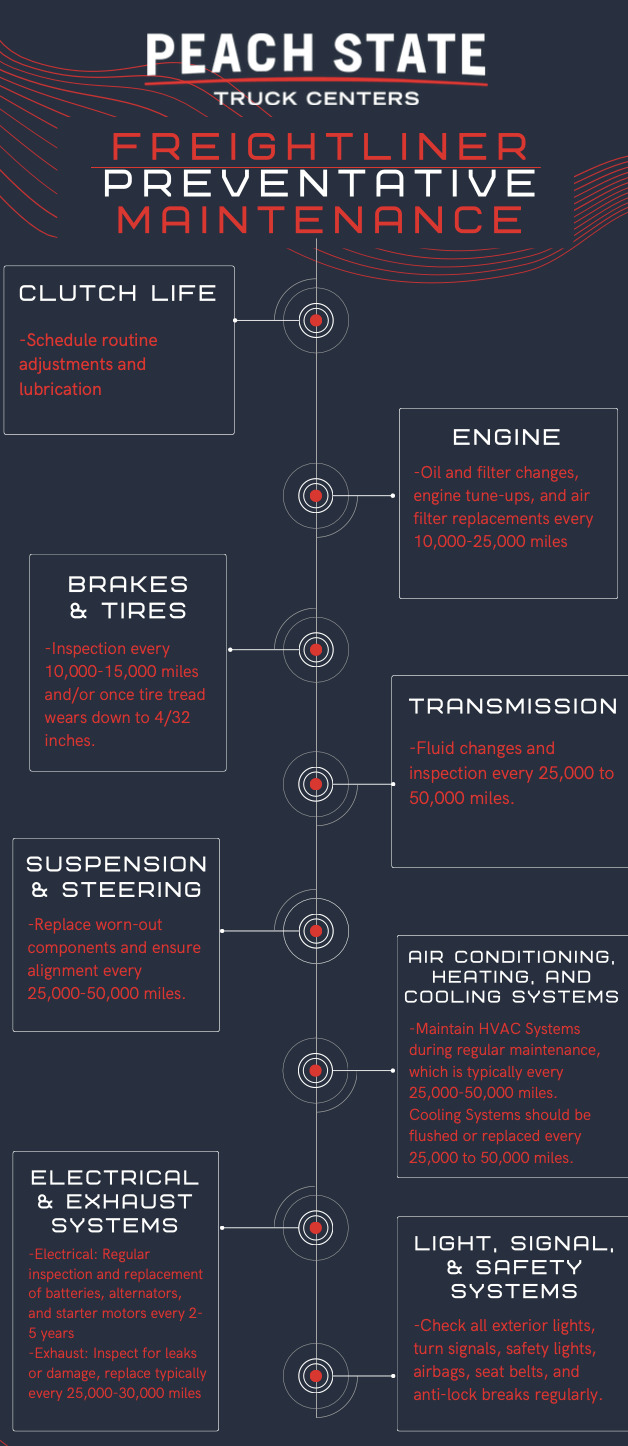

Preventative Maintenance Checklist

Clutch

A clutch in a Freightliner truck is a mechanical device that connects and disconnects the engine from the transmission. It allows the driver to change gears and control power transmission, enabling smooth acceleration, deceleration, and shifting of the vehicle. This essential component is used to engage or disengage the engine's power to the wheels, facilitating gear changes and maneuverability.

Clutches typically have long life cycles, with the ability to withstand hundreds of thousands of miles. However, this is only if preventative maintenance is applied.

How to Extend Clutch Life

- Scheduled adjustments based on manufacturer recommendations (can be self adjusting or may need a service technician)

- Lubrication applied at scheduled intervals

- Avoid leaving your foot on the clutch, even the smallest amount of pressure can put strain and wear on the clutch

- Pull away smoothly and gently

- Shift up naturally

- Don’t use your clutch as a brake

When to Replace Clutch

- Engages sporadically when pressed or fails to engage

- If you are having a hard time getting the truck in the proper gear

- Making squeaking noises when or when not it use

Cooling System

A cooling system in freightliner trucks, as in most vehicles, is a crucial component designed to manage and regulate the temperature of the engine to prevent overheating. The primary components of a typical cooling system in a freightliner truck include the radiator, thermostat, cooling fan, and water pump.

Cooling System Repairs

Flush or replace your cooling system to prevent overheating and engine damage every 25,000 to 50,000 miles.

How to Flush Engine Cooling System

- Ensure engine is cool before starting and park your truck on a level surface

- Remove the radiator drain plug and drain coolant

- When draining coolant, drain into a container and dispose

- Reinstall drain plug and fill radiator with distilled water

- Start the engine and let it run until it reaches normal operating temperature, then allow the engine to cool and drain again

- Add coolant system cleaner to the radiator

- Refill radiator with distilled water

- Start the engine again and let it run to circulate the water and cleaner

- Drain the engine again, then fill with 50/50 mixture of coolant/antifreeze and distilled water

- Start the engine to circulate the coolant

- Reinstall radiator cap and take the truck for a short test drive to ensure cooling system is working correctly

Electrical System

The electrical system in a freightliner truck consists of batteries, wiring, and various components that control functions like engine ignition, lighting, sensors, and electronic features, essential for the vehicle's operation and safety. Maintenance and troubleshooting are crucial to ensure reliability and safety.

Freightliner Electrical System Maintenance & Repairs

In order to have a high functioning electrical system in your freightliner, regular inspection and replacement of worn out batteries, alternators, and starter motors is encouraged every 2 to 5 years, depending on their condition. Replacing the entire electrical system in a freightliner truck is an extremely complex and time-consuming task, typically reserved for professionals. Your monthly or annual service appointments are a great opportunity to have those with extensive knowledge and expertise check these components.

Fuel System

The fuel system in a freightliner consists of a fuel tank, fuel lines, and a fuel pump responsible for delivering diesel fuel to the engine. The system ensures the engine receives a consistent supply of fuel for combustion, and advanced models may incorporate additional components such as fuel filters and injection systems to optimize performance and emissions. Proper maintenance and fuel quality are essential to ensure efficient and reliable operation of the freightliner truck. Proper maintenance of the fuel system includes making sure that it is clean and free of contaminants by changing the fuel filters and inspecting fuel lines.

How to Change Fuel Filters

- Ensure the engine is cool and truck is parked at surface level

- Turn off the engine and disconnect the negative battery terminal

- Locate the fuel filter (typically near the engine or along the frame rail)

- Loosen the fuel cap to relieve the pressure in the fuel system

- Remove the old fuel filters

- Apply a small amount of clean diesel fuel to the rubber gasket on new filters

- Install new filters

- Prime the fuel system

- *Warning: Different engines require different tools to prime the fuel system after replacement. Review your freightliners manual or contact your dealer before this step.

- Check for leaks and tighten connections if necessary

Fuel Line Inspection

- Examine fuel lines for signs of wear, corrosion, damage, cracks, leaks, etc

- Replace damaged lines

- Tighten all connections

- Start the engine and check for fuel leaks after completing inspection and repair

Additional Freightliner Parts in Need of Preventative Maintenance

- Engine: Regular oil and filter changes, engine tune-ups, and air filter replacements every 10,000 to 25,000 miles.

- Transmission: Fluid changes and regular inspections every 25,000 to 50,000 miles.

- Brakes: Routine brake inspections and replacements of pads, rotors, and brake fluid every 10,000 to 15,000 miles.

- Tires: Proper tire inflation, rotate tires every 10,000 to 15,000 miles, replace when tread wears down to 4/32 inch.

- Suspension and Steering: Replace worn-out suspension components and ensure proper alignment every 25,000 to 50,000 miles.

- Exhaust System: Inspect for leaks or damage, replace components as needed, which is typically every 25,000 to 50,000 miles.

- Air Conditioning & Heating: Maintain HVAC systems during regular maintenance, which is generally every 25,000-50,000 miles.

- Fluids: Check and top fluids (steering and windshield).

- Lights & Signals: Check that all exterior lights, turn signals, and safety lights are working.

- Safety Systems: Inspect safety features such as airbags, seat belts, and anti-lock brakes.